Introduction to faceting with the jamb peg

Would you like to cut all the standard commercial shapes, quickly, easily and as good as your eyesight will allow? Then read on.

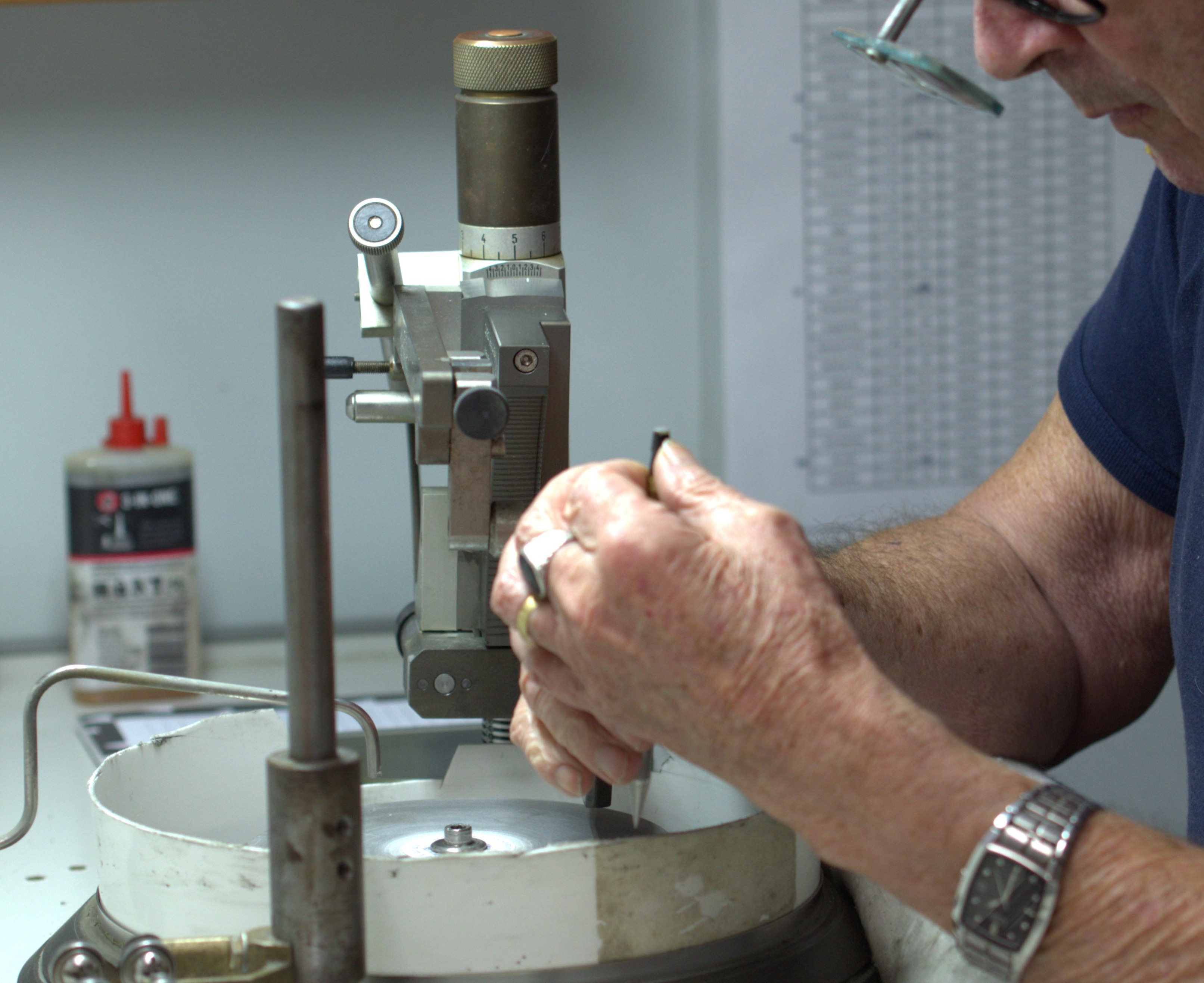

I had the chance to try out a modern jamb peg overseas, the machine was a modern industrial jamb peg. using a 64 index dopstick for most of the commercial cuts and a 48 index dopstick for trillion style cuts.

The machine is highly accurate and there are no parts to wear out, learning curve is abut the same as for any other faceting machine. I've been using mine for about 25 years and never had a problem.

There are a lot of negative comments regarding stones cut on the jamb peg. There are different styles of these machines (see Justin K Prim's "A Brief History of Jambpeg Faceting" on the video page. The jamb peg is used commercially and they are used for speed. There are cutting factories where they cut 20-30 stones, maybe more, a day. so you can't make comparisons between a Jamb peg used for commercial faceting and one used for precision hobby faceting. If these machines are set up correctly then achieving perfect facet meets is not a problem.

I'm quite sure if you tried to cut the same amount of stones on a mast machine or a hand piece machine the cutting would not be so good? I also wonder how good a stone the commercial Jamb Peg cutters could produce if they were being paid $50 - $80 ct. cutting fee?

My site is purely personal and relates only to the use of the modern jamb peg such as the BHandasa (Israel) and the KMT Brahm and Som (India) and was never intended to be a proper tutoriaI, I show enough to cover the basics, and hopefully get you interested. What I show here is the way I do it, and if you go about the right way it's not hard and in only a few hours you will be cutting your first stone.

Bob Lakey