First SRB

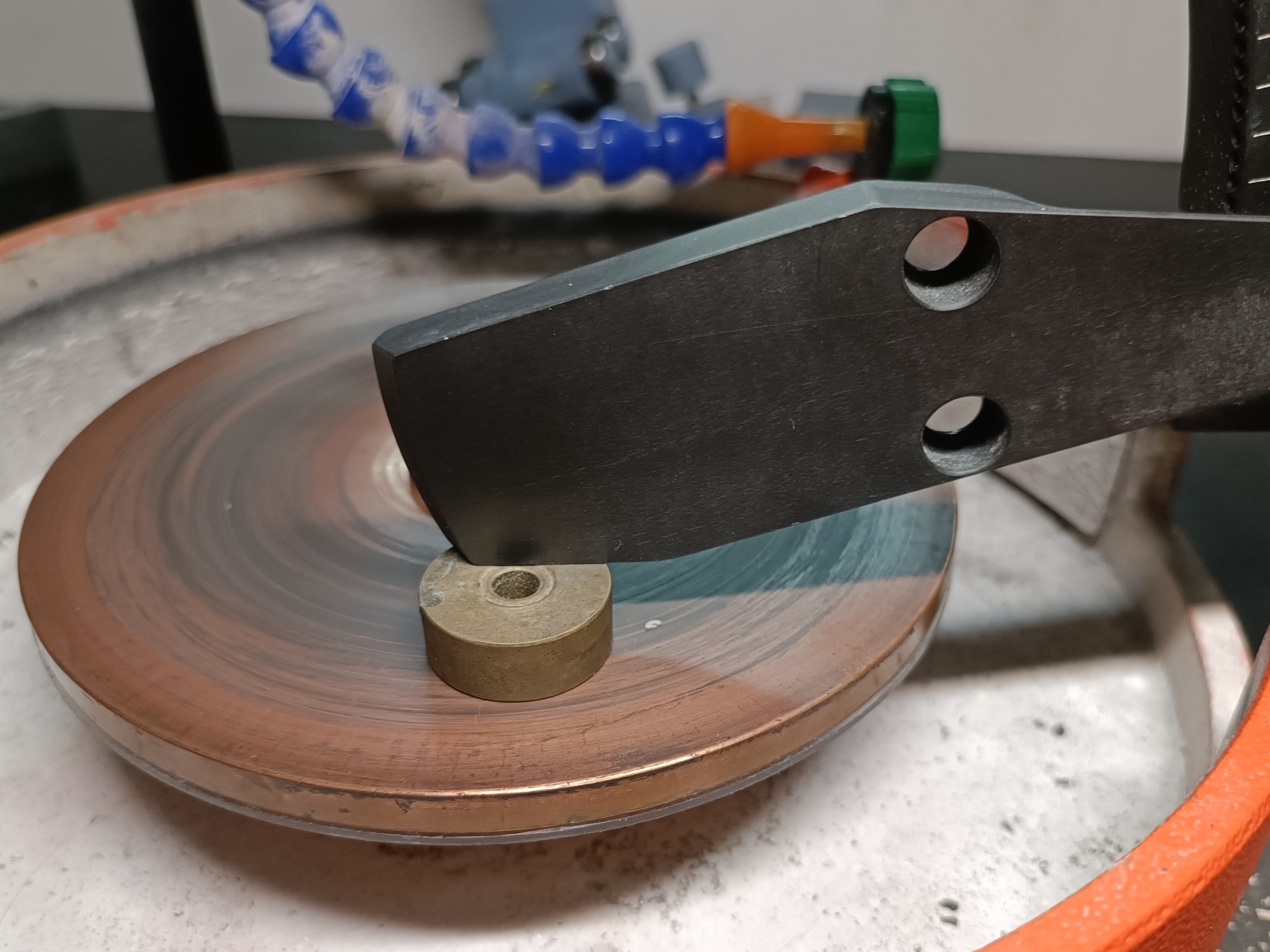

Cut the table first then start the main facets, I start with number 10 on my machine, yours may be different, it will be obvious if it's too low or too high, so make the adjustment, keep the table about 50%.

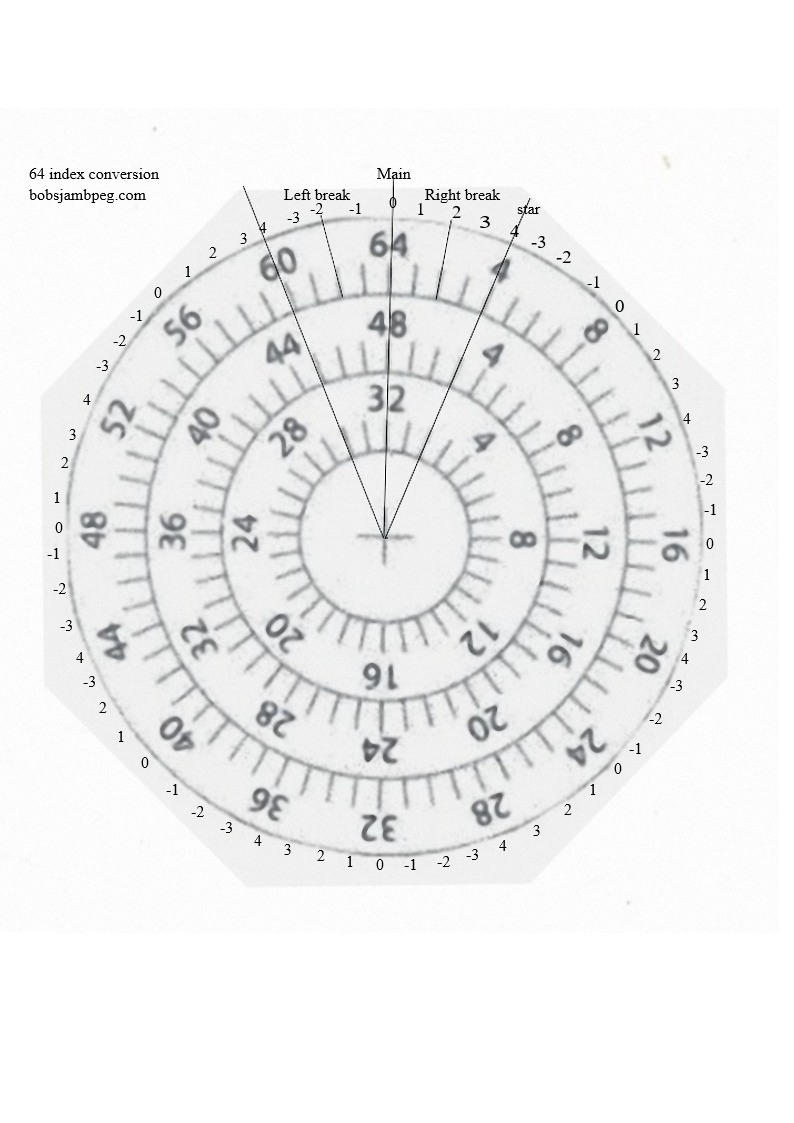

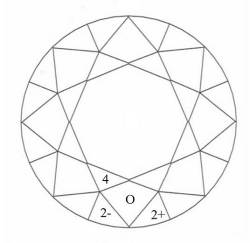

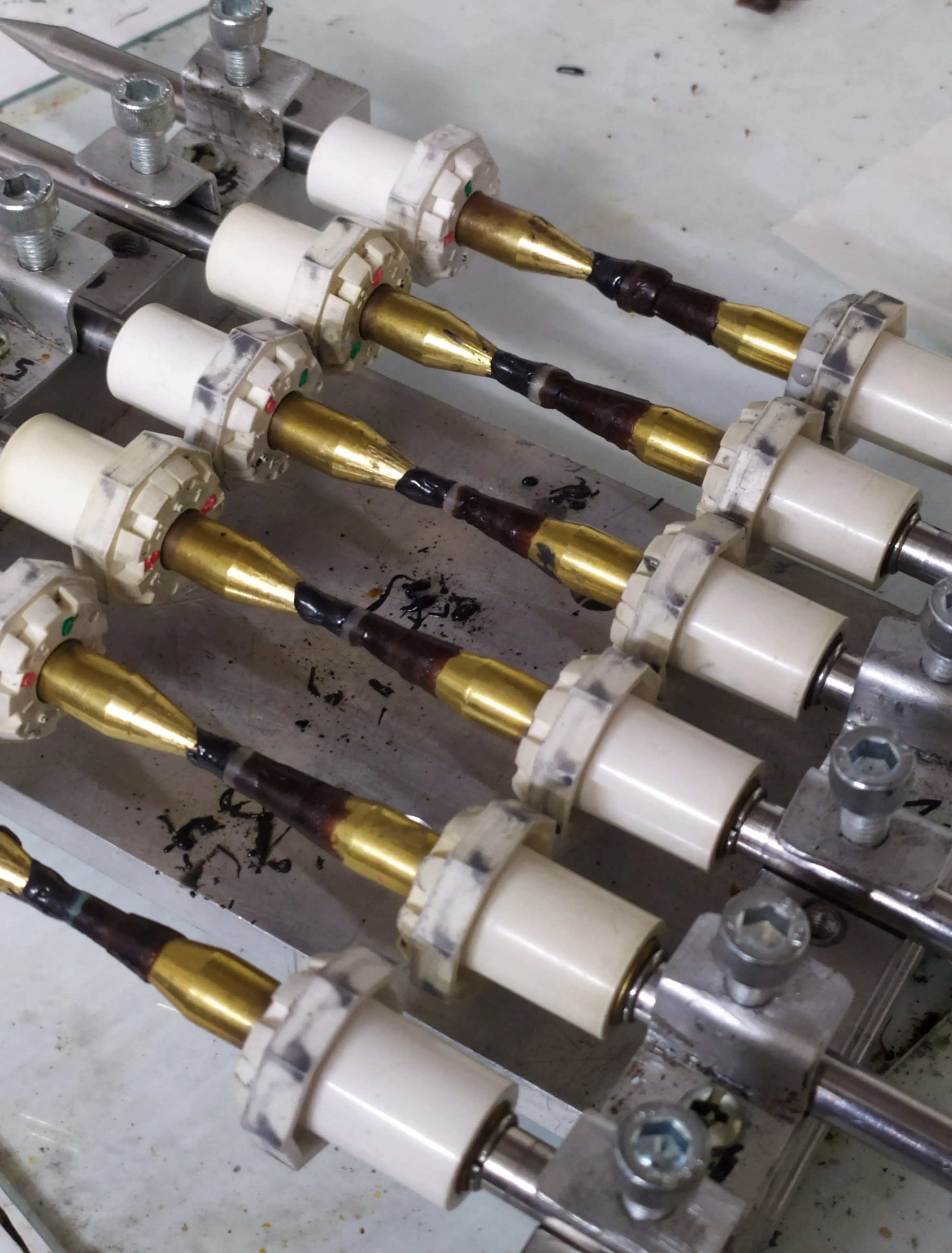

Now for the pre-polish lap. Pre-polish the table and mains, set the index to 4, star setting, just touch the lap on number 15 on the quadrant first and this will give you an indication whether the angle of the cut is too high or too low, may have to drop it to 14.5, you will see when it looks right, Now for the break facets, try number 8.5 on the head to start with, index set on minus 2 for left break facet, just touch the lap to get an idea of where the facet will be, you may have to move up to number 9 or down to number 8. When the facet looks right go ahead and cut the 8 left side facets, don't over cut. Now do the same for the 8 right side break facets with index set on plus 2. Avoid using the mast height adjustment, if you can't make perfect facet meets on the numbers you chose, fix theses meets at the polishing stage.

I polish table first, then stars, mains and break facets last. If you polish the mains first it is highly likely you will have to go back and touch up the mains because you have over cut a star or two.

You will make mistakes on the first few stones but it won't take long for it to all come together and then mistakes are rare.

To get a trouble free polish make sure you have a good pre-polish, no rough edges.