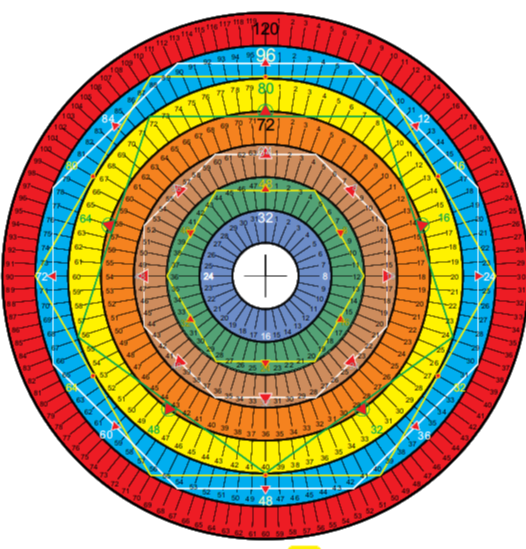

64 index & 48 index are all you really need, there is not much you can't do with these two indexers.

All the indexers and pre-formers printed with ABS like resin.

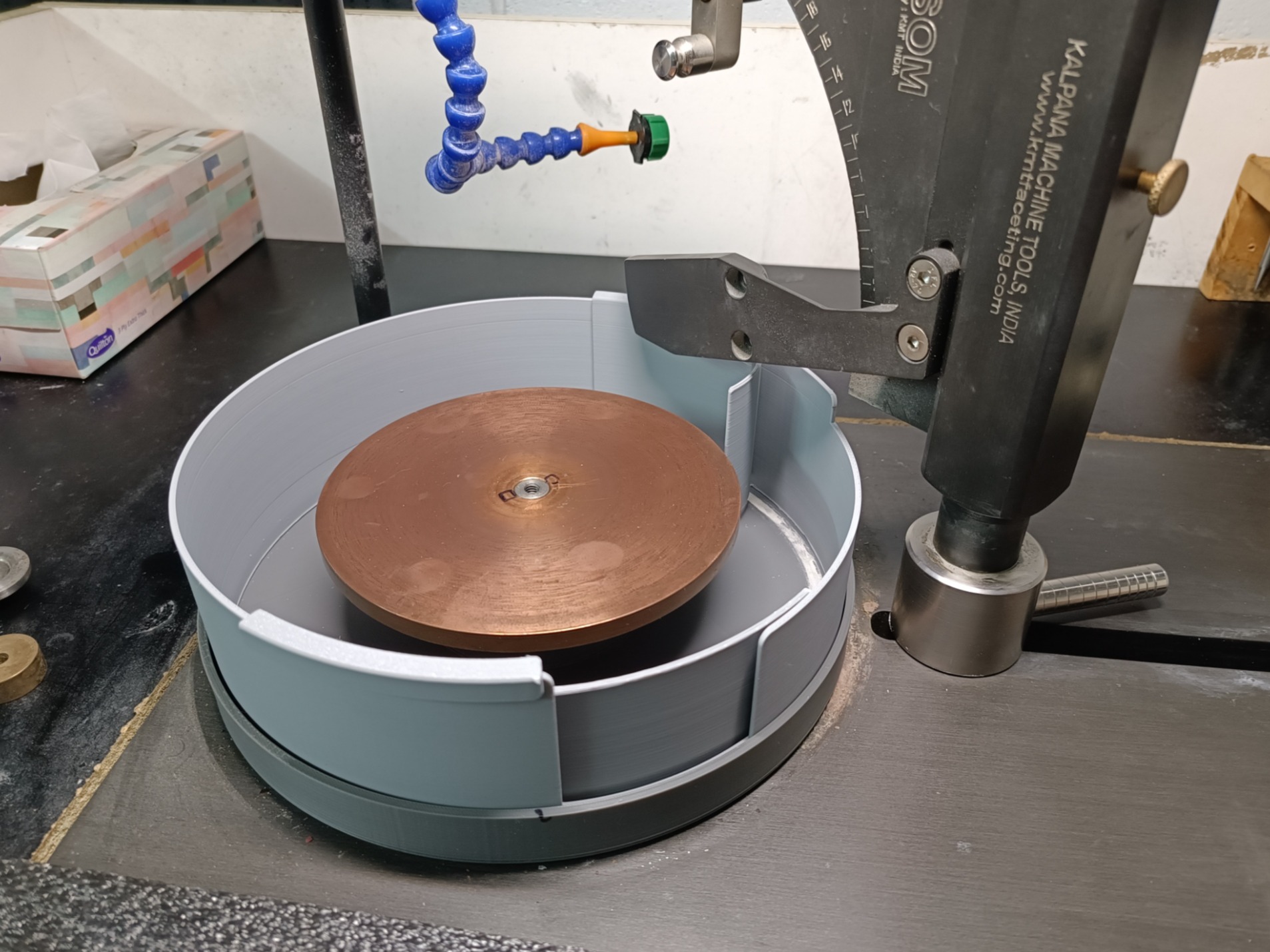

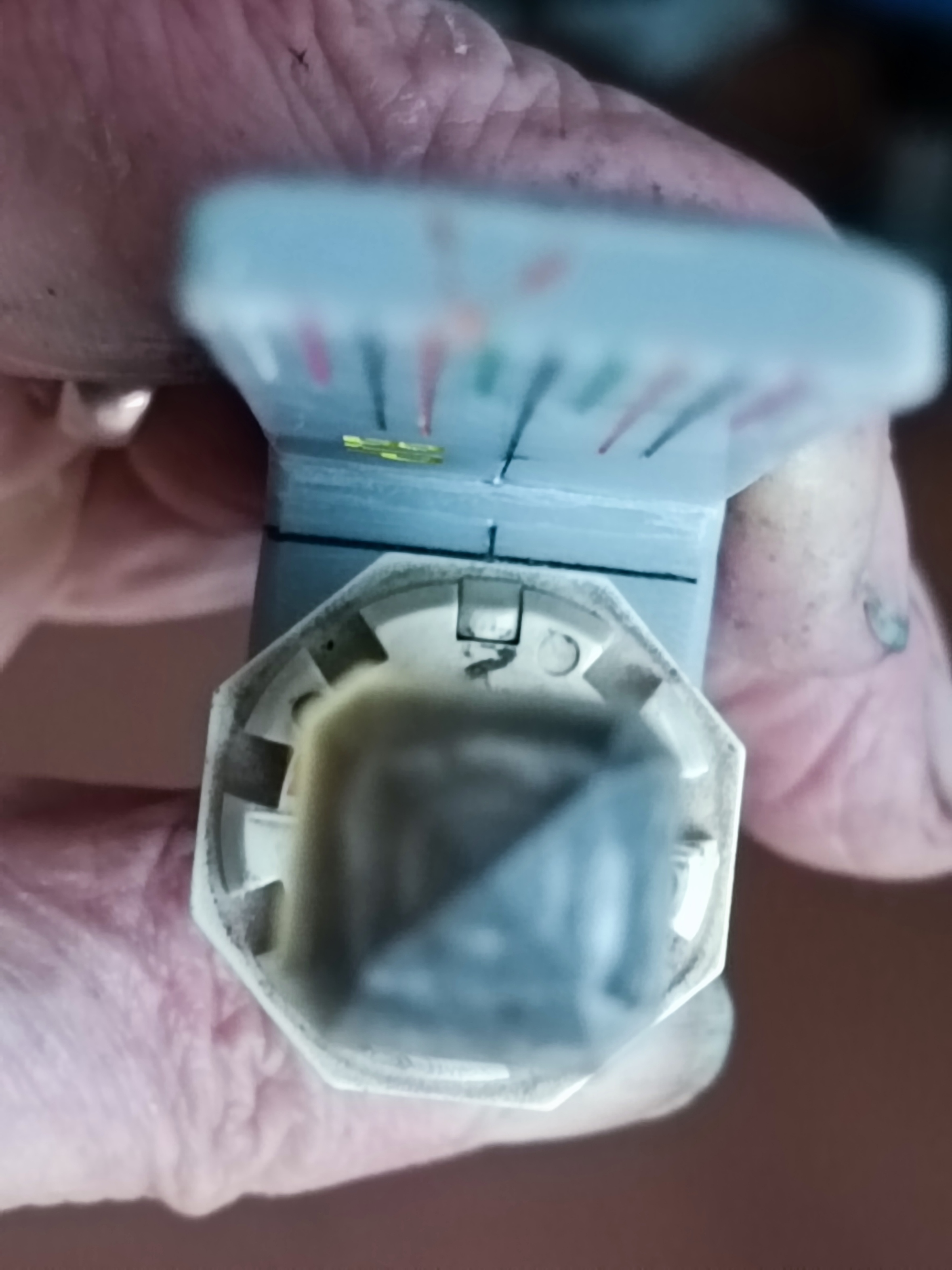

New 64 index dops from KMT

The new 64 index dops from KMT are a vast improvement on the old ones. Make sure you check the flats for flatness, If there is an imperfection a quick wipe across a grinding lap will fix it.

96 index

The 96 index will cover most published designs, but not all. For example a trilliant can be cut but it's difficult because the mains on the trilliant design do not correspond to the mains on the 96 index.

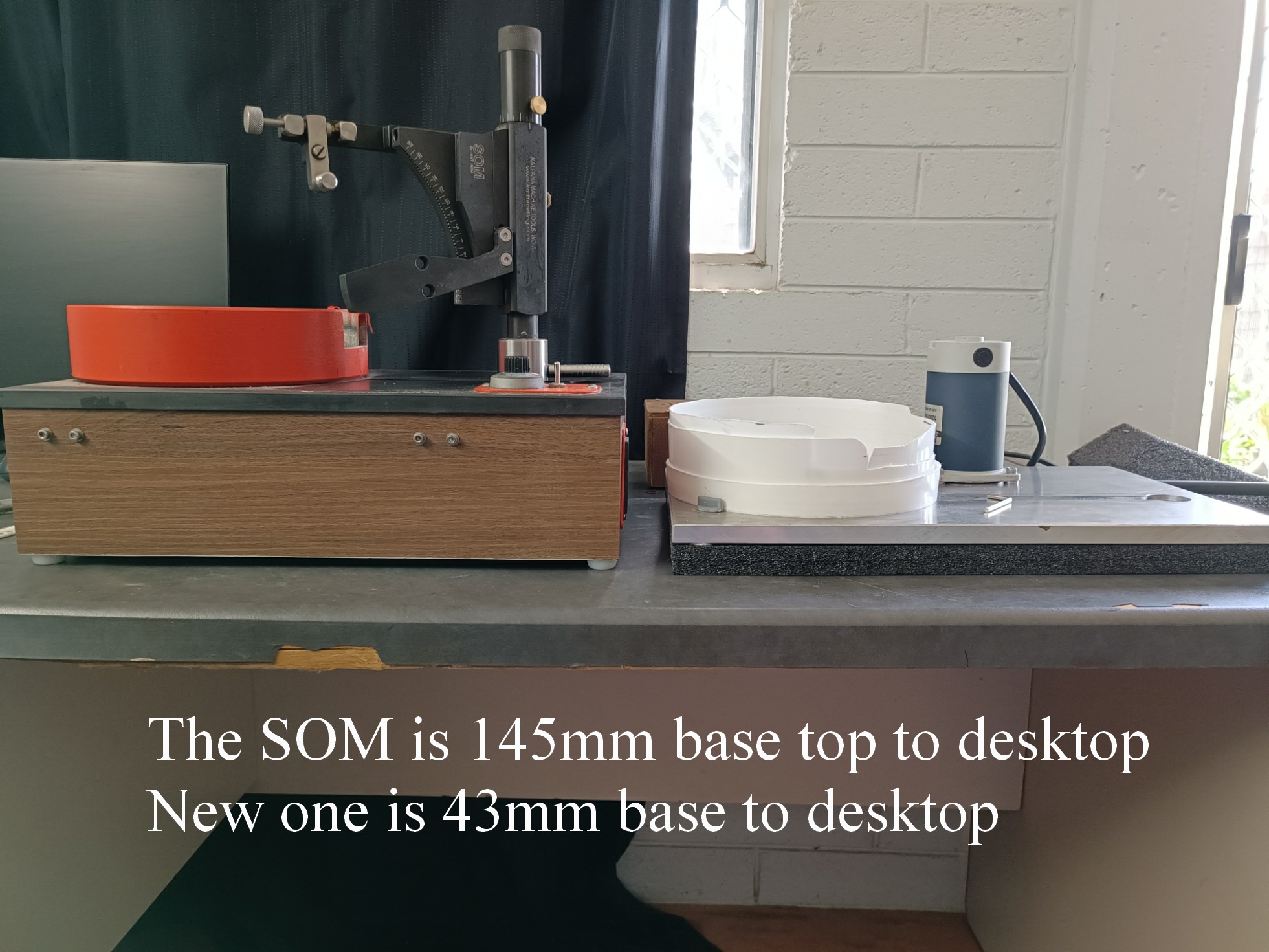

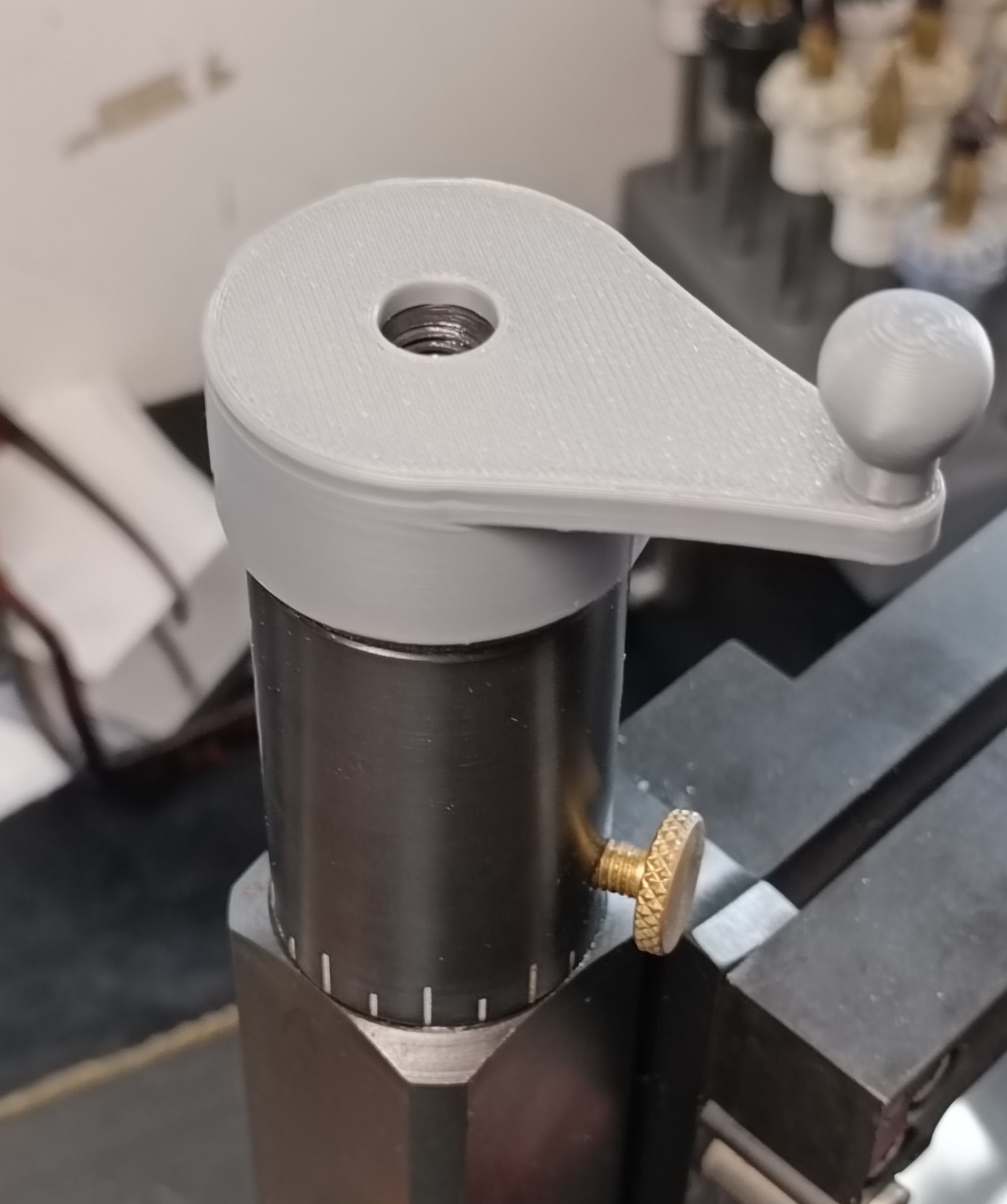

Oversize full 96 index

The standard indexer is approx 25mm flat to flat. this one is 35mm so bigger teeth and more usable, a 5mm spacer is needed to use it.

May be useful for a complicated design.

42 index

This is a 7 sided full 42 index, only cut a couple of stones so far but seems to work ok.

64 full index

This is an experimental full 64, works fine and should last, only 4 indexes are used to cut a round brilliant. I also made a 96 index but the teeth are very small so may not last.

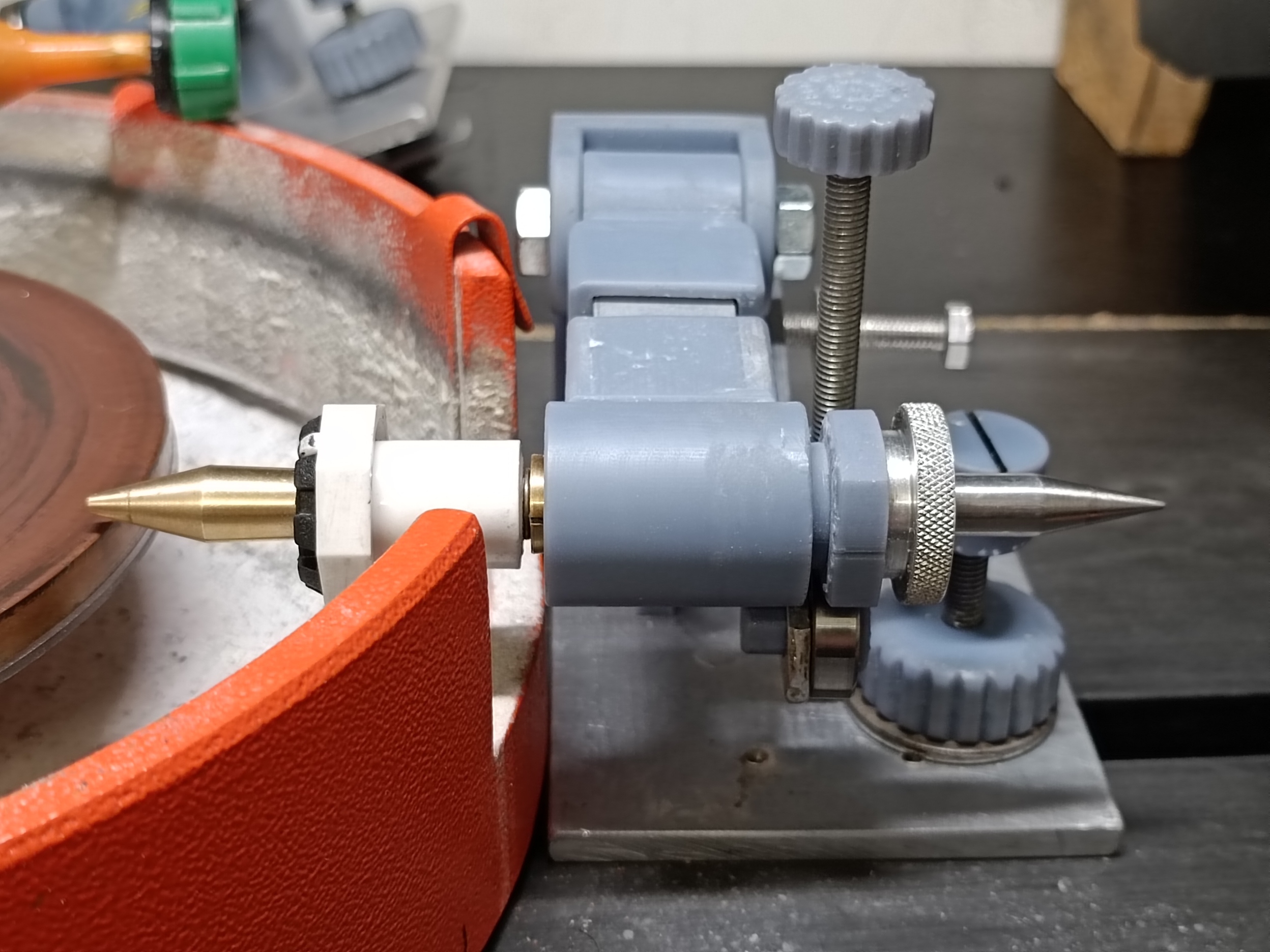

Full pre-former with cams

This is a full pre-former using cams. Works well but I only use it to form sides and ends on cushion cuts. Using it for other shapes can be very wasteful, I prefer to pre-form by eye.

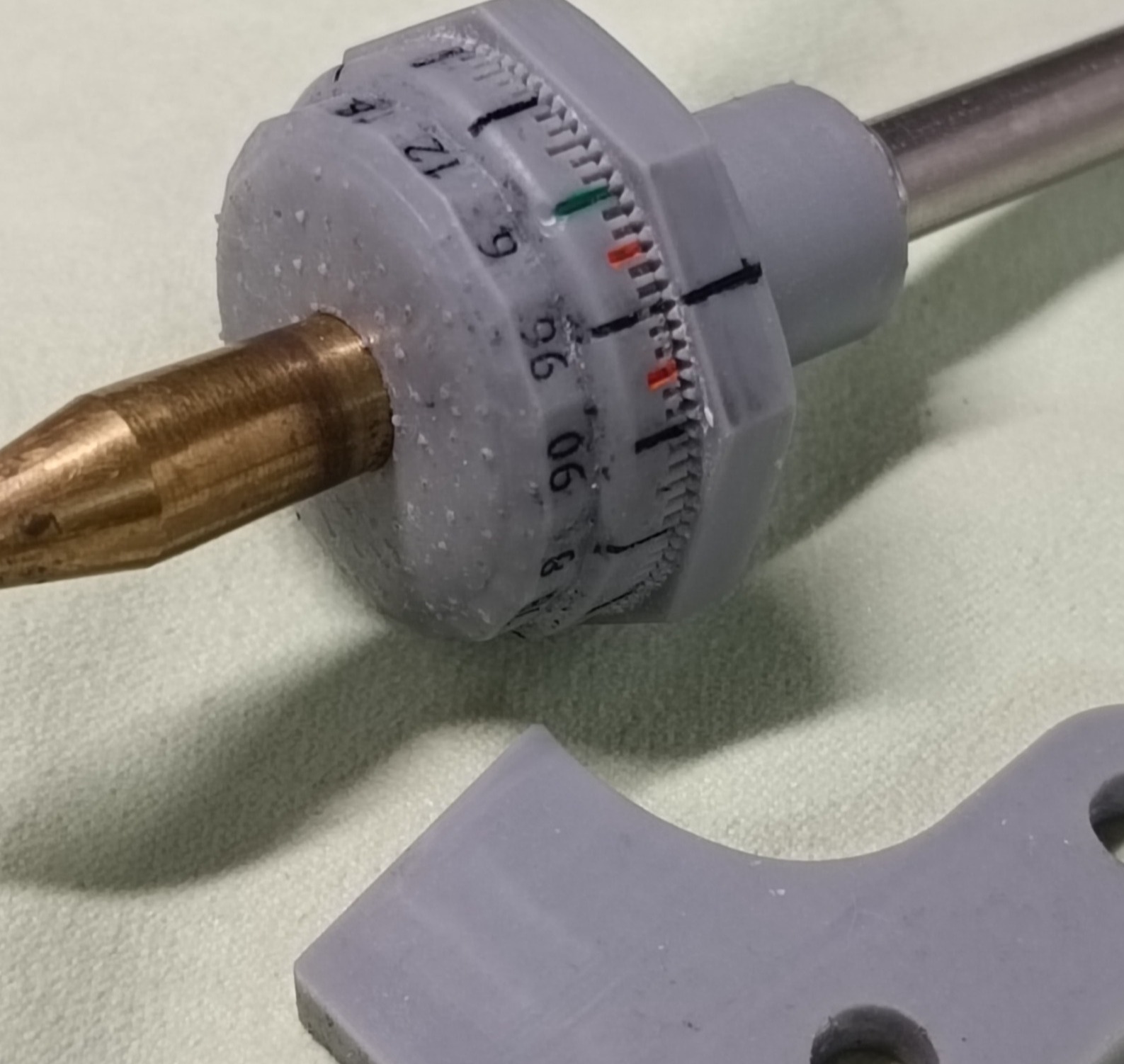

Rounding Pre-former

This simple pre-former is only for rounds, working quite well, but requires the same diameter for all the dopsticks. This pre-former is available, if interested please email me.

Rounding Pre-former

This is my preferred rounding pre-former. Different diameter dopstick are not a problem. Very easy and quick to use.

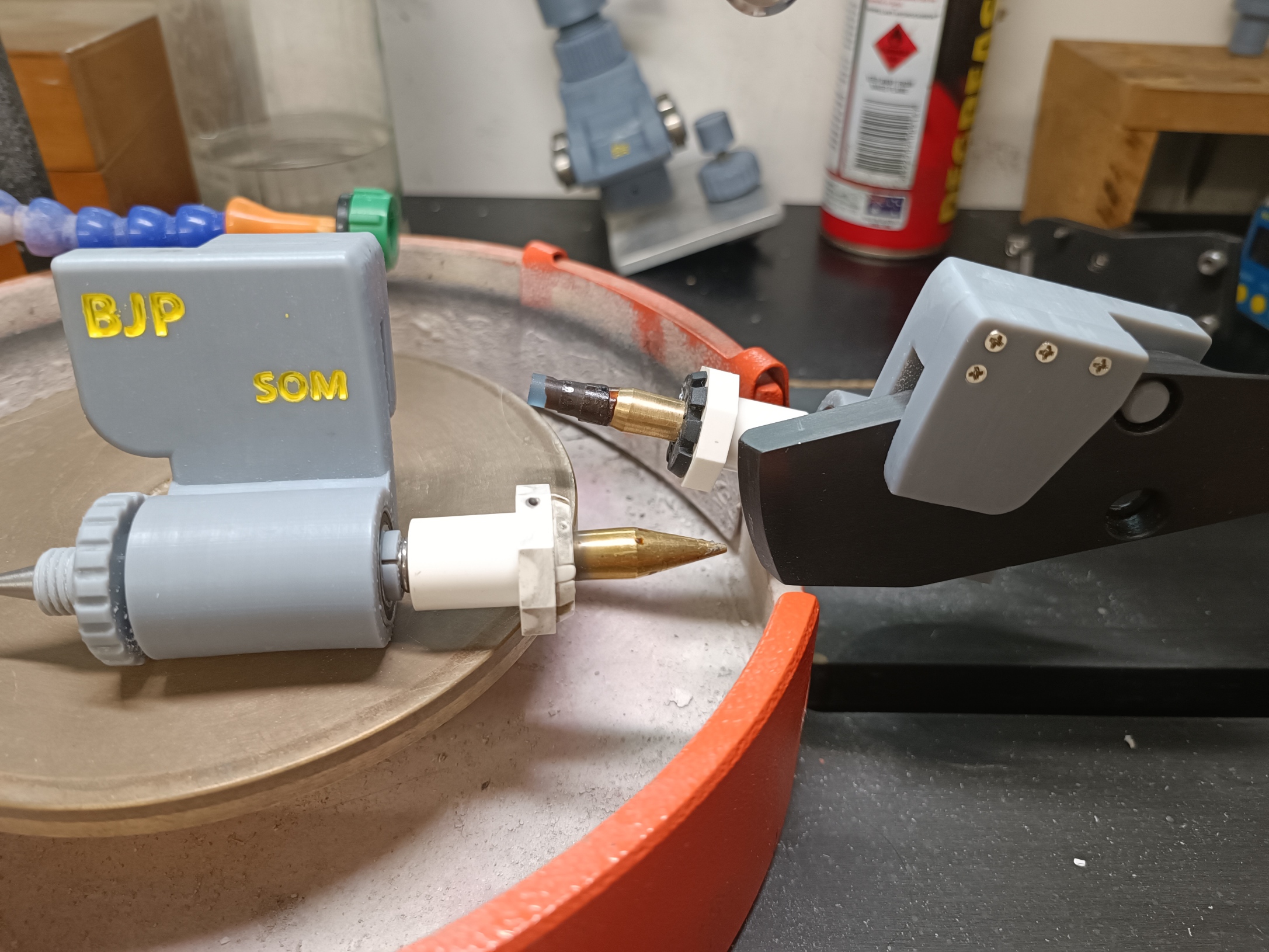

Transferring gauge

When transferring stones by eye there is usually some adjustment to be made after the transfer to get a good girdle. I made this tool to try to improve the process. Seems to work quite well.

Line it up

Emerald cut or square is aligned to the gauge, now the stone can be centered and girdle leveled. Use the same method for the pre-form.

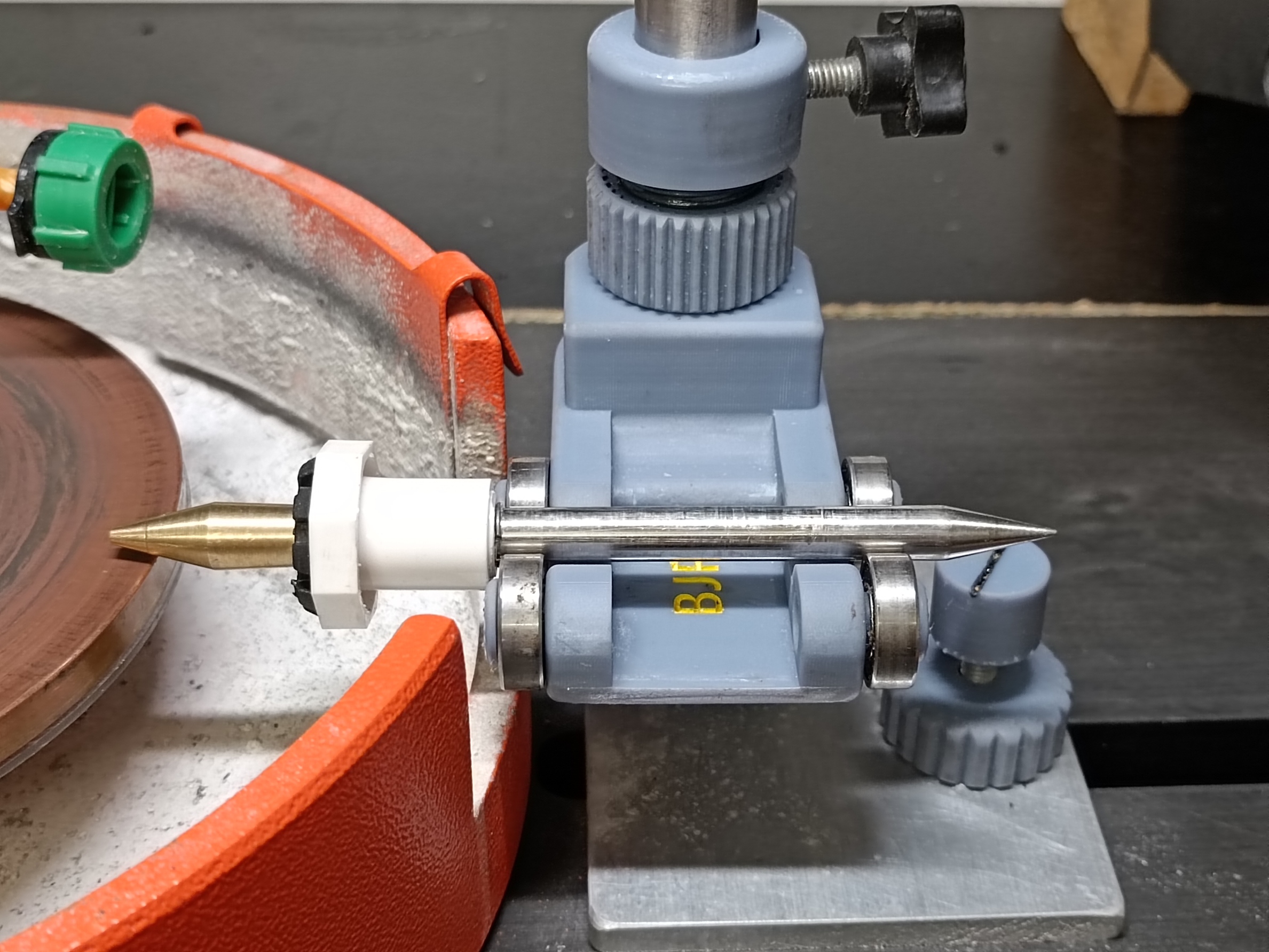

Lined up

By keeping the dopstick centered between the lines and the dopstick aligned as in the previous photo, then parallax is not a problem.

Centering

Just need to move the stone slightly to the right. The alignment may not be 100% perfect but will be better than the usual method of just sighting the stone or using the faceplate and getting it close.