Setup

The jamb peg is quite capable of faceting a stone with perfect meets, just as accurate as a mast or handpiece machine. But it must be set up correctly, this is the most important step in faceting with the jamb peg, it's the difference between cutting a perfect stone and frustration! Do it right and you will be faceting great looking stones in no time. This set up will should apply to all jamb peg machines.

The modern Jamb Peg is a highly accurate and exceptionally well built industrial faceting machine. I've been using mine for for more than 20 years and never had a problem. If the machine is setup correctly then the final result is up to the operator. Check out the Som or Brahm machines in the "where to buy ?" page

This machine has an rotating mast assembly so that any flat girdle can be cut, emerald, square, free form etc. An alternative method is needed for rounds. All other shapes can be pre-formed by eye. There is a table attachment which is very efficient, easy and fast, reverse is needed to use it.

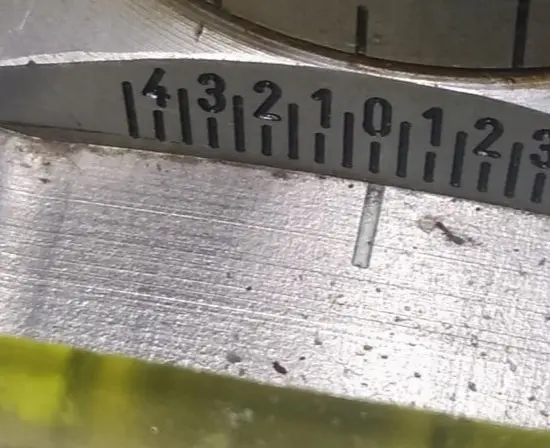

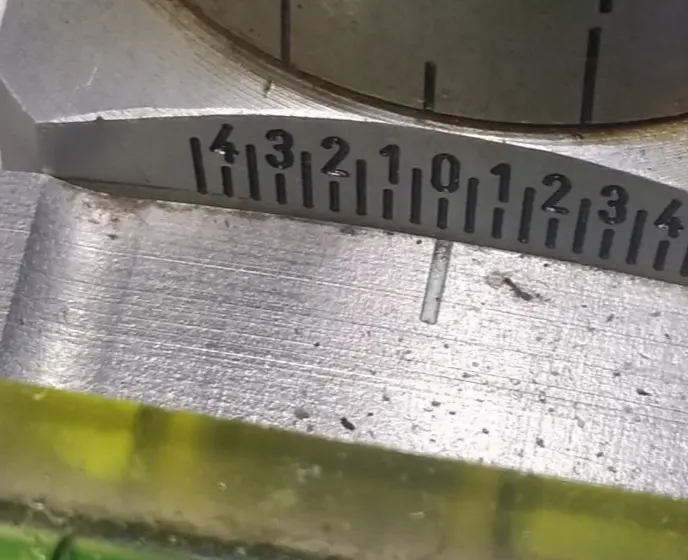

Squaring the arm to the master lap is critical for getting perfect facet meets, if it's not done, then you won't get good meets. Use an engineers square to check the lap is 90 deg to the side arm of the machine, use the cheater to square it up, then take note of the cheater makings as this will be your starting point for every stone you cut. Get this right and you should get perfect facet meets and girdles. This also applies to the Som.