Usefull Add-Ons

Some for the IF-10 but most work fine for the KMT SOM

There is no provision on these machines to individually preform a round girdle. the picture shows a simple home made pre-former which just slips on to the arm. works quite well but the dops need to be uniform in size.

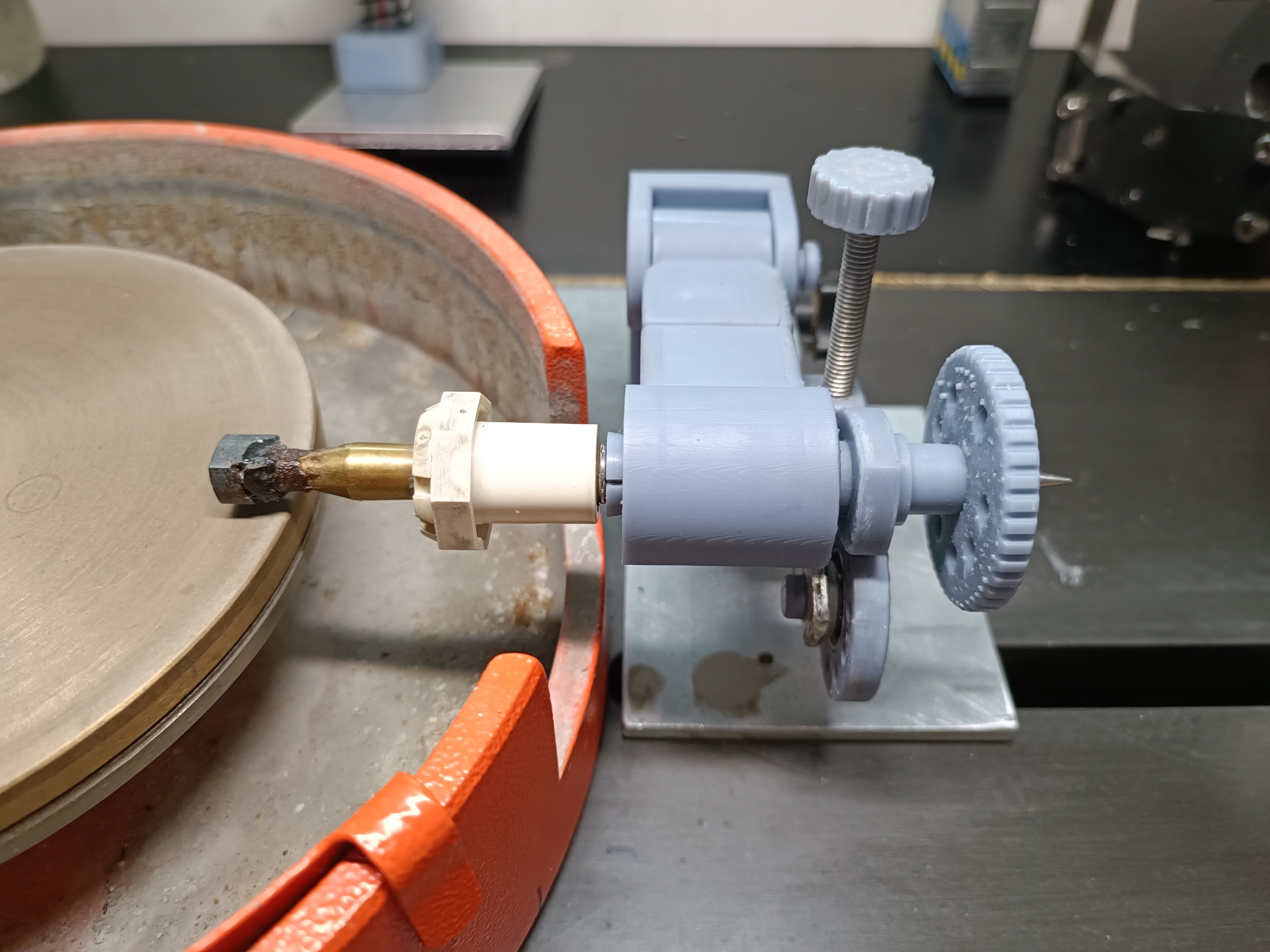

This version of the 4 bearing pre-former is the one I prefer, very quick, accurate and there is no problem if the dops are not uniform in size.

This is a full pre-former I printed for ovals, pears, cushions etc. Like the previous one it just sits on the base so no need to remove the mast to use it. I would use it for calibrated stones or just to give me even curves on cushions , ovals etc. when doing larger stones.

A simple block sits in the slot in the machine base, easy and quick to set up.

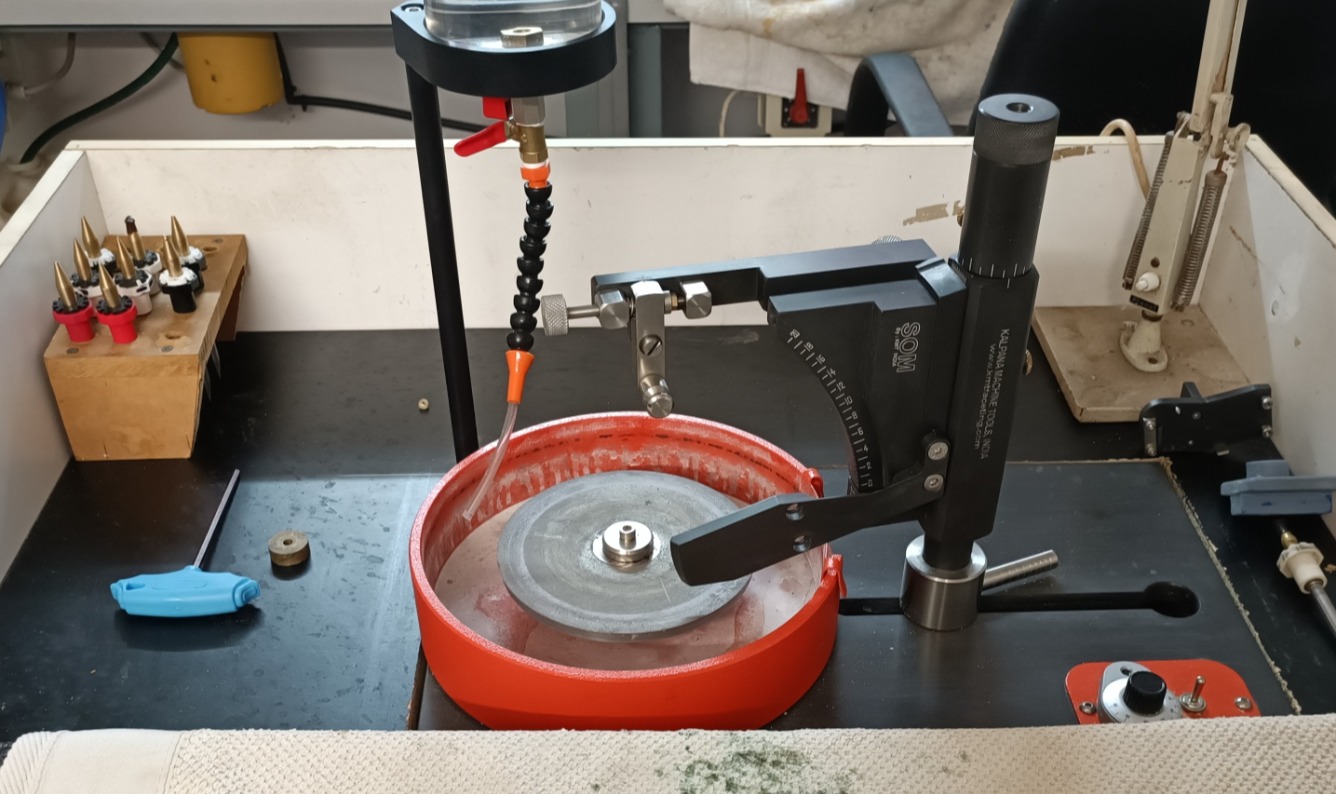

And last is my hard stop, a great time saver for rounds, just a simple piece of aluminium and a bolt. It can be used for angles from around 18 deg to 90 deg. If your stone is centred and you have a flat crown and the required depth, then when you get the crown mains equal, the rest of the facets should fit.

If I have, say, 5 small rounds to cut then by using the stop it takes about two minutes to complete the mains on all 5 stones. With small stones one facet overcut can ruin the stone as you have to recut all the other facets. Make another mistake and now the crown is too shallow! With the stop this doesn't happen.