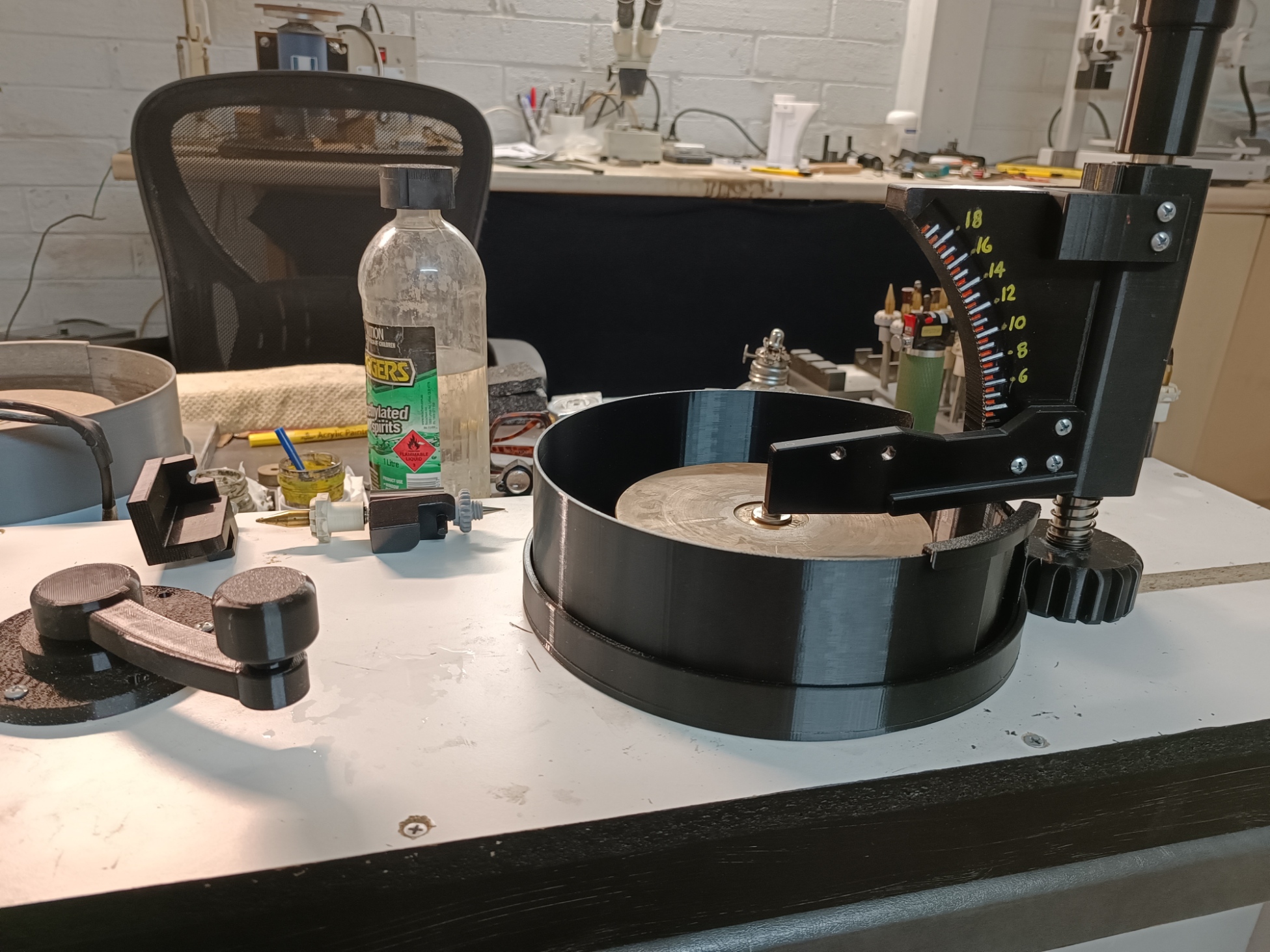

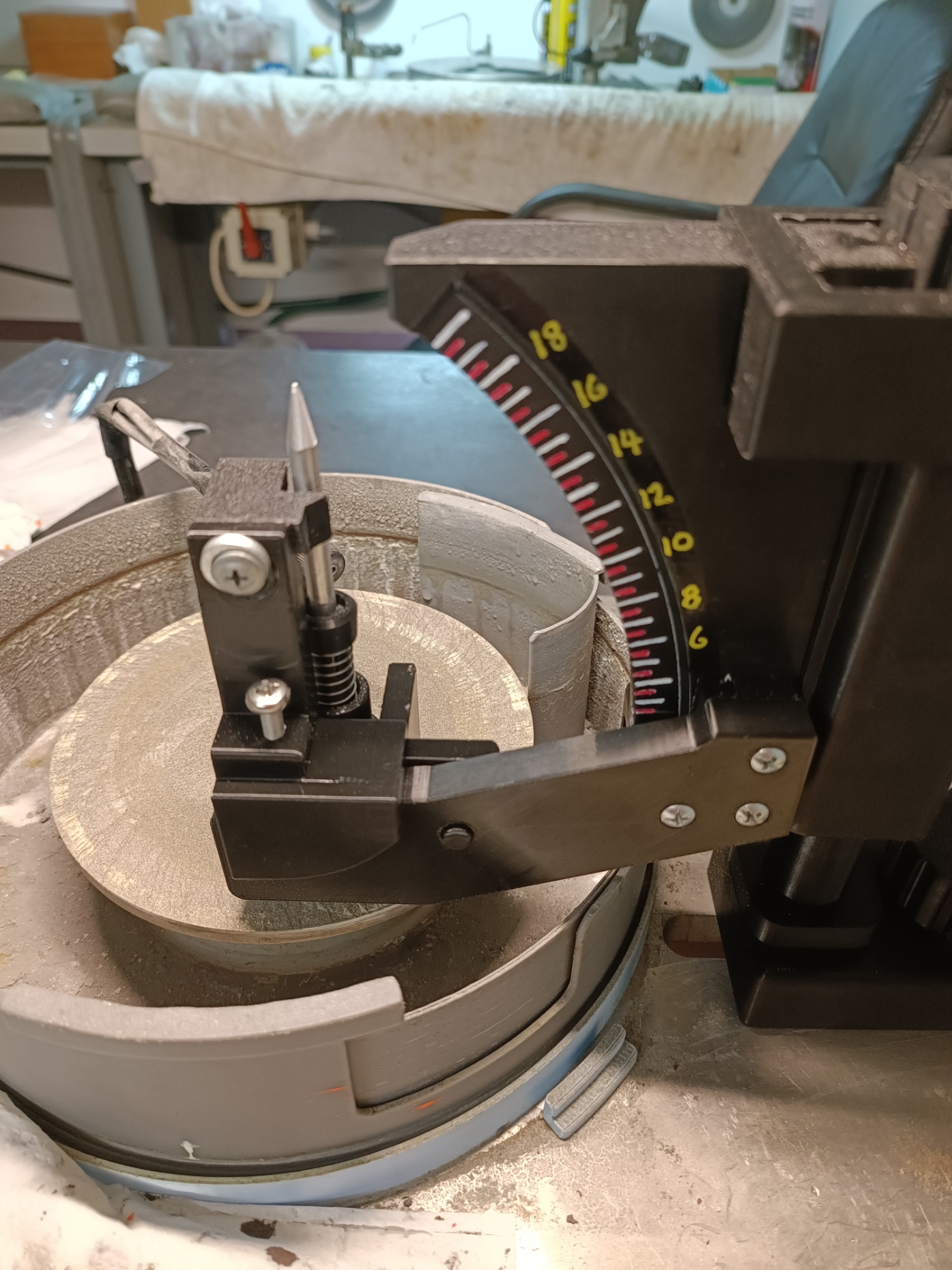

FDM printed hand crank jamb peg V1

My new project was to come up with a hand cranked portable jamb peg and also to be useable on my low profile base

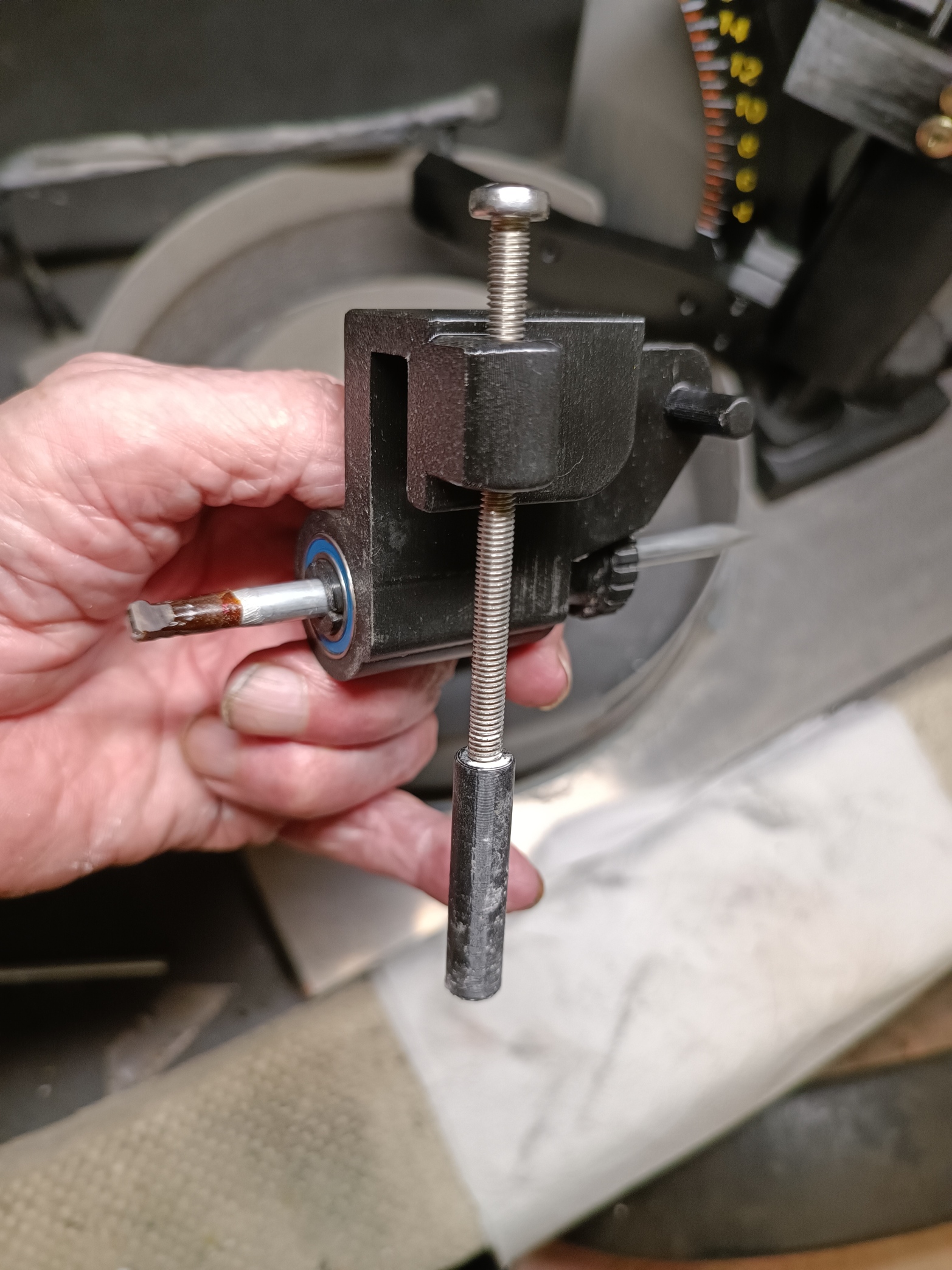

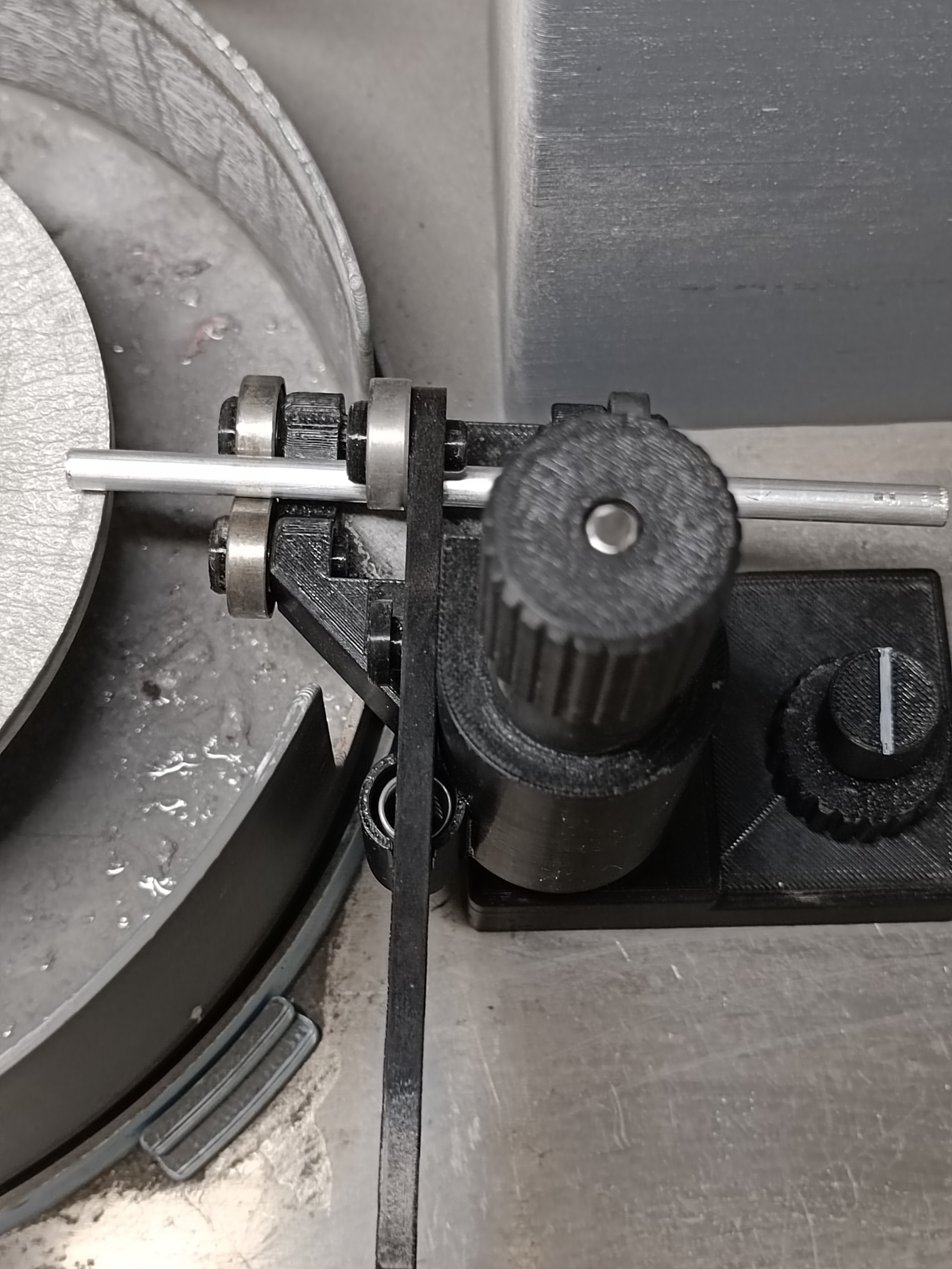

Since I started 3D printing indexers for my other jamb pegs with a resin printer I often wondered if it would be possible to print a usable faceting machine, The build plate on the resin printer was fairly small, fantastic detail, but print size small. So bought a FMD printer so I could print larger pieces. The prints turned out better than expected, so went ahead and started doing the drawings. There were certain aspects of the machine I wanted which aren't available on the others, So apart from the radius of the quadrant the drawings were done on the fly.